The client is a leading Malaysian cold chain logistics enterprise specializing in temperature-controlled storage and logistics services for frozen and refrigerated foods. Its operations span core segments including warehousing, transportation, and sorting. The company has earned widespread trust through advanced facilities and a professional team. Committed to technological innovation and sustainable development, it continuously advances the intelligent upgrade of its warehousing and logistics systems, striving to become a benchmark cold chain logistics enterprise in Southeast Asia.

Project Challenges:

The client's existing warehouse operations faced two core challenges:

1. Traditional cold storage relied on manual labor for handling, sorting, and inventory checks, resulting in low efficiency and frequent errors like misplacement or omissions due to human oversight;

2. Weak information technology infrastructure and the absence of a professional warehouse management system led to inefficient inventory management and order processing.

Project Scale:

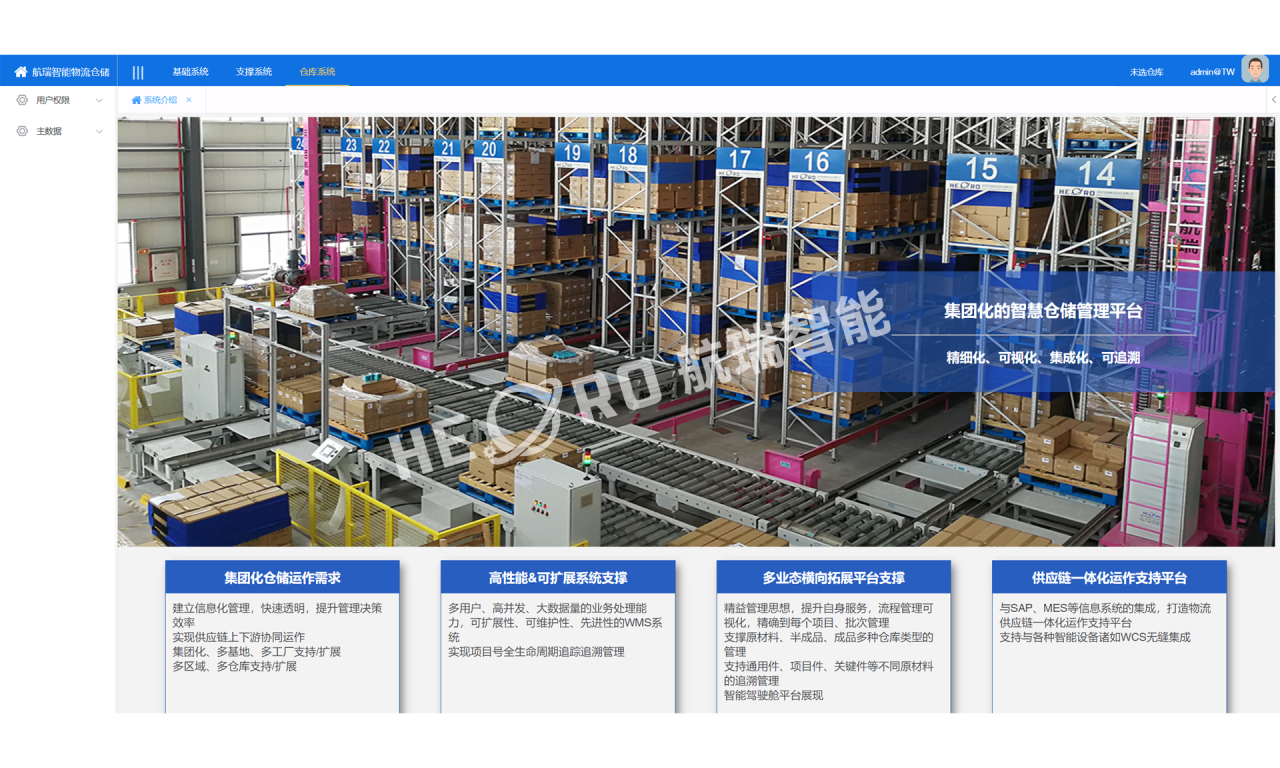

The project spans approximately 2,500 square meters, with a ceiling height of 23m and a planned total of 10,208 storage locations. It utilizes 1.2m × 1.2m × 1.5m pallets with a 1-ton load capacity, equipped with automated devices including double-deep stacker cranes, RGVs, conveyors, and elevators, along with a complete refrigeration system. One set each of WMS (Warehouse Management System) and WCS (Warehouse Control System) is deployed simultaneously.

Project Highlights:

1. Integration of automated equipment including stacker cranes, RGVs, and conveyors enables automated operations for goods handling, sorting, and inventory counting. This significantly boosts operational efficiency, reduces human error rates, and alleviates labor intensity for staff.

2. Utilizes high-rise racking combined with high-density storage technology to scientifically optimize warehouse layout, increase storage capacity utilization, and facilitate efficient goods access and management.

3. Implements a WMS system for intelligent upgrades in inventory management, order processing, and data analytics. This enables real-time inventory tracking, streamlined order fulfillment workflows, and data-driven decision support to enhance customer satisfaction.