Company News

GDXL × HERO Intelligence, a strong alliance to build automated three-dimensional warehousing system, to achieve the intelligent upgrading of warehousing!

GDXL Precision Machinery Co., Ltd. is a national high-tech enterprises, specializing in new “small giant” enterprises, but also the PET mold national standards drafting unit, focusing on PET bottle blowing molds, injection molds and cap molds R & D and manufacturing. Its self-built testing center has been certified by CNAS and has become one of the four major accredited laboratories of Coca-Cola (the only one in Asia-Pacific).

The products are exported to more than 40 countries and regions in the world, including America, Asia-Pacific region, Europe, etc., and the customers cover Coca-Cola, Pepsi, Nestle and other international famous brands, and the blowing molds accounted for 20% of the global high-end market share, and the Asian market share ranked first.

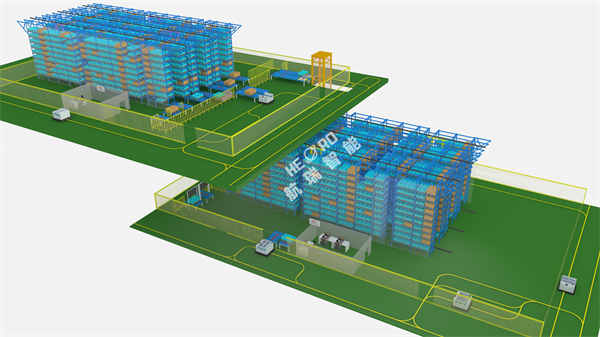

In order to effectively respond to the challenge of shortening the customer delivery time, GDXL and HERO Intelligence to build a cross-floor double library linkage automated three-dimensional warehousing system, designed to promote the automation and intelligence of warehousing and logistics to enhance the speed of response.

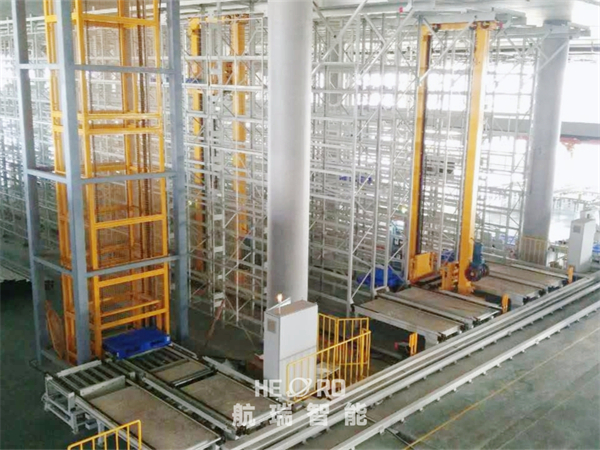

The project is located in the center of the new site of the GDXL Industrial Park, respectively, on the first floor and the third floor with two three-dimensional library, and through the elevator to achieve connectivity between the two libraries, forming a complete automated three-dimensional warehousing system. The first and third floors are surrounded by precision processing workshop area, and the second and fourth floors are surrounded by office area. The design of the three-dimensional warehouse gives full consideration to the needs of material storage and handling, and each three-dimensional warehouse is connected to two floors, so that the materials can be sorted in the order picking area on the first floor, and then quickly distributed by AGV to the various workstations in the workshop.

Project highlights:

1. The project adopts 9-meter high-level three-dimensional shelves with a total of 3,800 cargo spaces, which significantly improves the utilization rate of storage space and fully meets the demand for material storage.

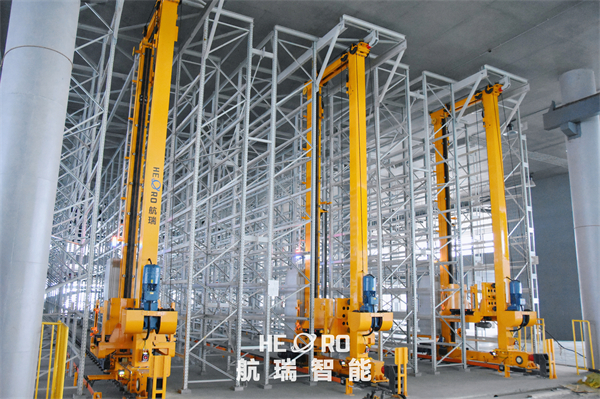

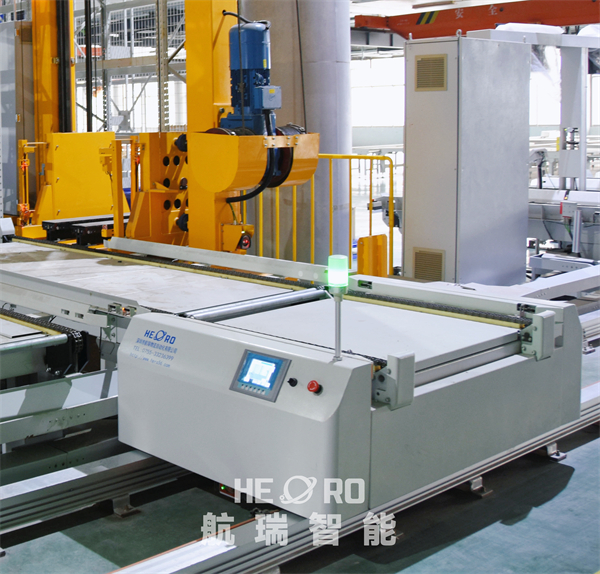

2. Integration of silent stacker cranes, AGV, RGV, elevators and conveyors and other intelligent equipment, to build an efficient and smooth logistics system, to achieve the material in the three-dimensional warehouse - the production line of the two-way flow of precision, so as to enhance the overall operational efficiency.

3. Intelligent warehousing system realizes seamless connection and cooperative operation among equipments, which improves the overall performance and stability of the system, and at the same time, facilitates maintenance and upgrading, and reduces the operation cost.

4. The deployment of small-piece picking and ordering system accelerates the process of small-piece material picking and ordering, and enhances the accuracy and efficiency of material handling.

5. The stacker cranes adopt silent design, effectively reducing noise pollution during operation and optimizing the working environment.