Company News

HERO Intelligent Empowers Wision Furniture's Fourth Factory to Build a Fully Automated Logistics Center, Achieving Intelligent Upgrades in Warehousing and Logistics!

Deeply committed to the “Internet+Manufacturing” model, Wision Group continuously strengthens its technological barriers through independently developed robots, automatic warehouse, and intelligent logistics systems. This approach aligns closely with China's strategic development directions of “Deep Integration of Informatization and Industrialization” and “Industry 4.0.”

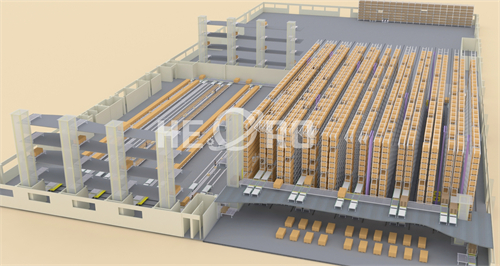

- Utilizes 19m high-rise racking with 7,972 storage positions, optimizing vertical space utilization and significantly boosting warehouse capacity efficiency.

- Coordinated operation of intelligent equipment including stacker cranes, hoists, and conveyors enables automated goods retrieval/storage and efficient material flow, substantially reducing labor costs and enhancing operational efficiency.

- Nearly 300 conveyors form an intelligent transport network exceeding 1,800 meters in total length, ensuring efficient and orderly inbound/outbound operations.

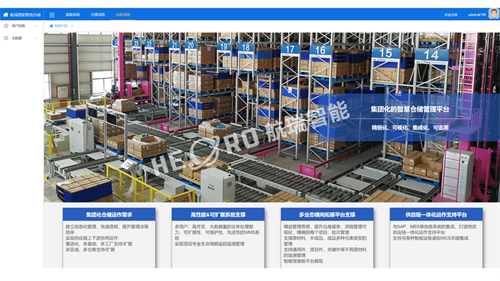

- Deployment of WMS (Warehouse Management System) and WCS (Warehouse Control System) enables real-time data updates and feedback, providing robust support for corporate decision-making.