Company News

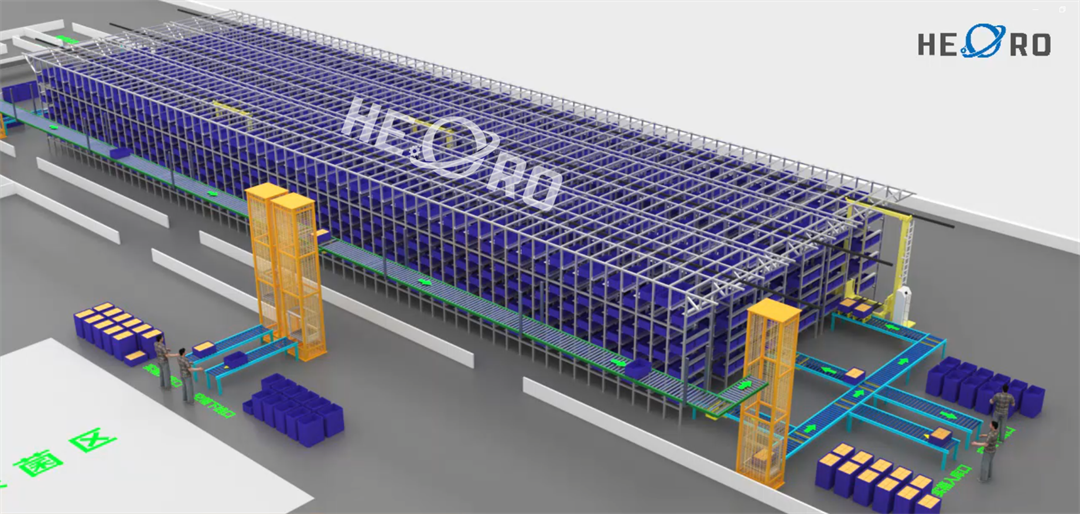

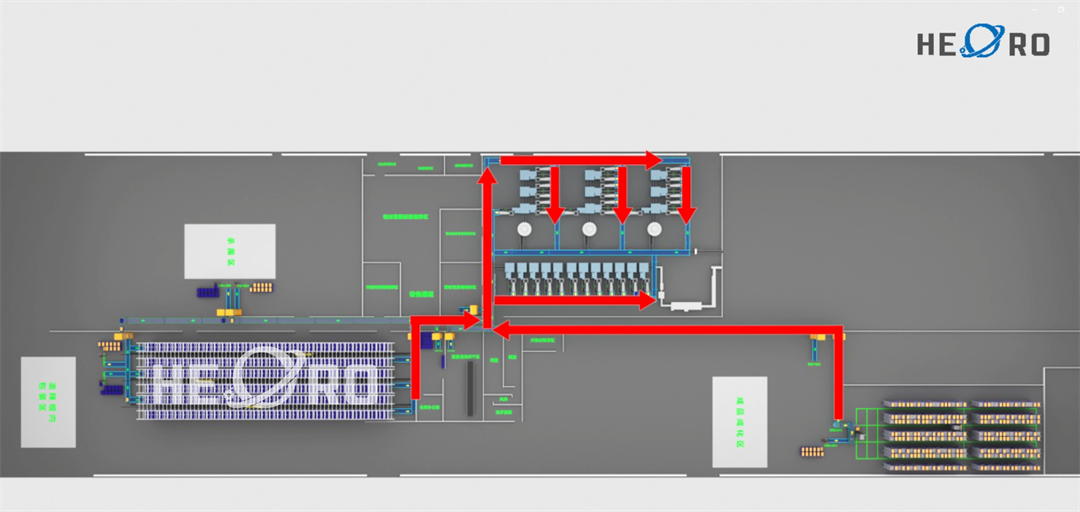

HERO Intelligent has customized a highly automated transfer warehouse and replenishment system for a food enterprise, achieving full-chain optimization from “raw material supply to replenishment and empty container recovery”!

Project Highlights:

1. Precision Flow Adaptation:

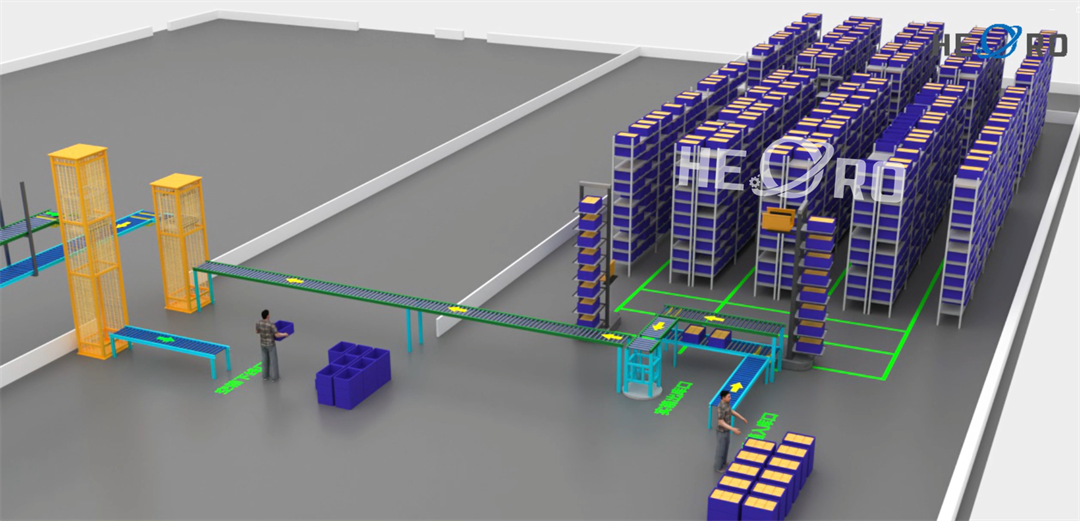

Tailored to material flow characteristics, the two raw material transfer warehouses utilize miniload and CTU storage modes respectively, enhancing retrieval responsiveness and space utilization.

2. Spatial Utilization Optimization:

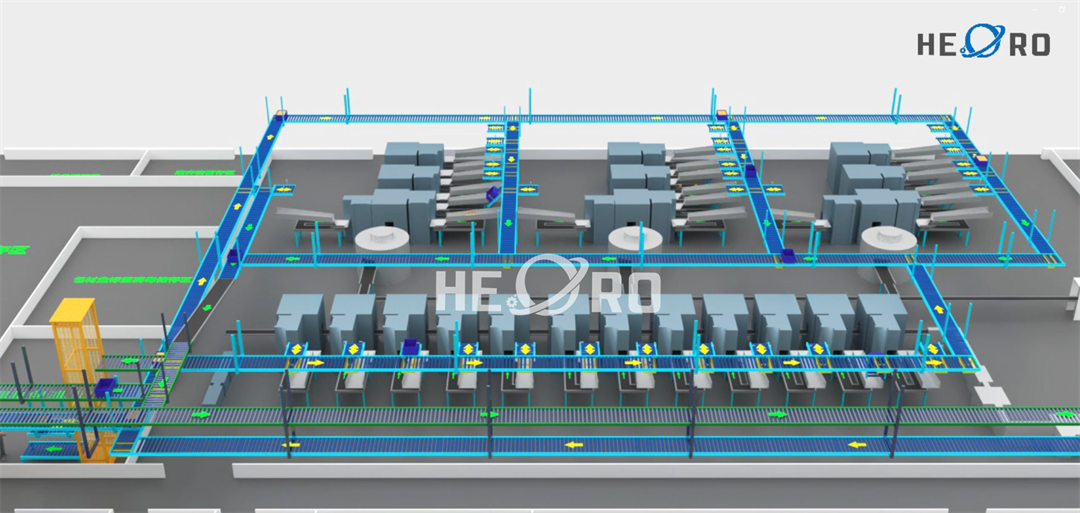

An innovative “dual-level overhead conveyor + elevator” combination extends logistics pathways vertically. This frees up ground-level production space while preventing interference between logistics and production processes, achieving optimized spatial resource utilization.

3. Integrated System Synergy:

Logistics operations across multiple workshops are consolidated and coordinated with intelligent equipment. This optimizes transport routes, minimizes cross-workshop handover points, and significantly enhances logistics efficiency and stability.

- PrevHERO Intelligent has developed a customized “Smart Warehousing + Automated Distribution” solution for a sanitary ware enterprise, empowering its intelligent upgrade in warehousing and logistics!

- NextAdaptable Across Multiple Industries, Automated Warehouses Emerge as Key Drivers for Cost Reduction and Efficiency Gains.