Company News

HERO Intelligent has developed a customized “Smart Warehousing + Automated Distribution” solution for a sanitary ware enterprise, empowering its intelligent upgrade in warehousing and logistics!

As the sanitary ware industry accelerates its large-scale production, enterprises face continuously rising storage demands for finished products, packaging materials, and purchased components. Traditional warehousing and logistics models have gradually exposed the following issues:

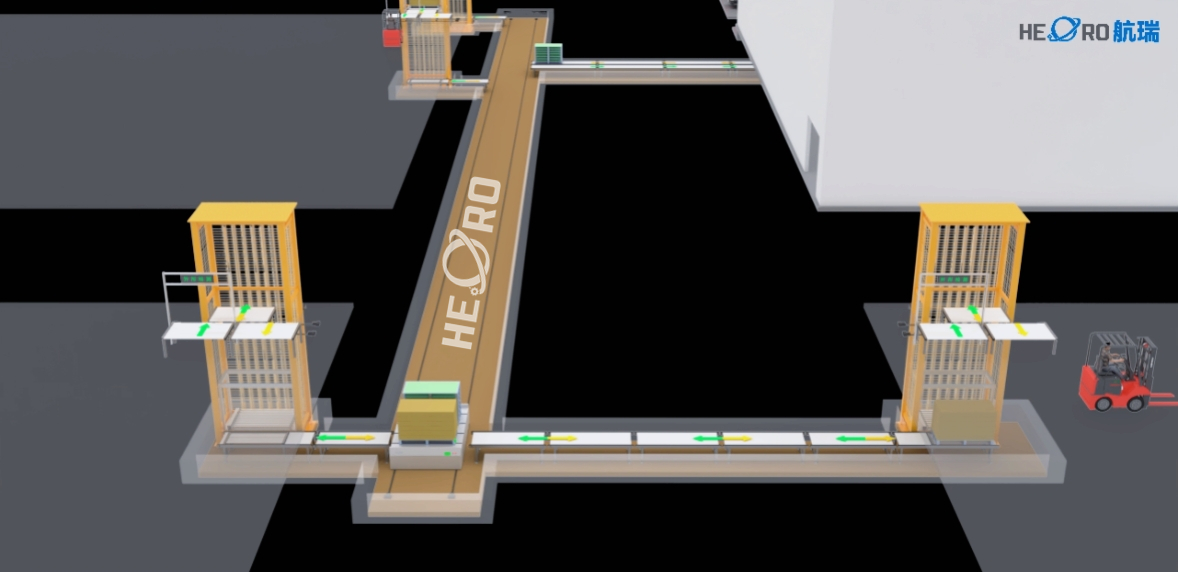

To effectively address these challenges, HERO Intelligent designed a customized vertical storage and automated distribution solution for a sanitary ware manufacturer. The 9,000㎡ facility features a 23m-high warehouse with a double-deep aisle layout. With 15,888 storage positions, each capable of holding 1,500KG of materials, it fully accommodates the diverse storage needs for finished sanitary ware, packaging materials, and purchased components. Intelligent equipment including double-deep stacker cranes, robotic arms, RGV rail-guided vehicles, and hoists operate in coordination to achieve automated material transport to workshops and automated inbound/outbound storage for finished goods.

1. High-density vertical storage significantly optimizes space utilization, effectively reducing land costs for the enterprise.

2. Innovative construction of an underground automated conveyor channel enables seamless integration between the assembly workshop and glass/hardware/aluminum material workshops, doubling conveying efficiency.

3. Integration of gantry robots and automated loading systems in finished goods outbound processes substantially increases loading efficiency while reducing labor costs.

4. Equipped with a visual cockpit displaying real-time core data including warehouse location status, equipment operation, and inventory dynamics. Simultaneously monitors assembly workshop progress, enabling digital enterprise management and transparent production logistics information to further enhance corporate image.

- PrevHERO Intelligent tailors automated storage systems and logistics rail solutions for printing enterprises, resolving the pain points of “unstable equipment + disjointed systems” in warehousing!

- NextHERO Intelligent has customized a highly automated transfer warehouse and replenishment system for a food enterprise, achieving full-chain optimization from “raw material supply to replenishment and empty container recovery”!